Our Products

We welcome

any question or requirment

Sand Plant Equipments

We are Manufacturer, Supplier, Exporter of Rotary Sand Drier, Fluidized Sand Cooler, Rotary Polygon Siever, Portable Vibratory Sand Siever, Deck Type Sievers, Sand Muller with Aerator, Intensive mixers, Belt Conveyor, Bucket Elevator, Screw Conveyor, Pneumatic Conveyor. Our setup is situated in Kolhapur, Maharashtra, India.

Ganesh rotary sand drier is specially designed to improve the quality of sand which ultimately reflects in quality and economy of castings. Moisture is removed from sand effectively. Ganesh sand drier is sturdy in design and rigid in construction. The drum body is specially designed to withstand high temperature of firing unit. To avoid the heat loss drum is wrapped with asbestos sheet. This machine is designed to for maximum sand drying capacity in minimum time. The sand is conveyed from one side to other with fin type screw conveyor. The drum is rotated on rollers. Requires less floor space and minimum oil consumption. Cone type sand drier and double drum type sand drier are also available.

• Capacity : 1 ton per hour to 5 ton per hour

• Designed to improve quality of sand which ultimately reflects in quality & economy of casting

• Fuel - Diesel, Kerosene, Crude Oil & LPG etc

• Available in compact double drum type design

• Requires less floor space & min, oil consumption

SMT fluidized sand cooler is specially designed to have a dust free return sand at constant temperature ensuring good mould quality.

• Ganesh fluidized sand cooler gives rapid and efficient cooling of sand.

• Capacity 1Ton per hour to 20 ton per hour.

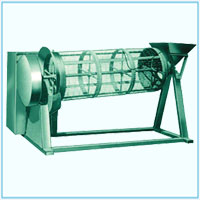

SMT rotary polygon sand seiver is designed to get the high quantity of sand.

• Capacity : 8 Ton to 10 Ton / Hr. (Dry Sand)

• Motor : 3 H. P. & Reduction Gear Box

SMT drum type sand Siever is intensively used in large and medium type foundry. The drum is fabricated and mounted on two rigid frames. The drum is wrapped with required M.S. mesh sieve. Sieve is replaceable.

• Capacity 8-10 ton per hour

• Fabricated drum mounted on two rigid frames

• Drum is wrapped with replaceable MS sieve

• Capacity : 8-10 TPH

• Motor : 2 H.P. & reduction gear box

SMT portable vibratory sand siever is specially designed for small foundries. The salient feature of this machine is that it can be moved easily moved at any corner of foundry. The pan is suspended and vibrated with unbalanced weight. The pan is designed in such a way that sieved sand goes in one direction and unsieved sand goes on other side.

• Easily moved at any corner of foundry

• Available in single, double & three deck models

• Capacity : 3 TPH

• Motor : 1 H.P.

SMT 2 deck and four deck sievers are designed to sieve two or four different grades of sands. These are special machines manufactured as per customer requirement. Pan is designed to ensure that no mixing of grades is possible.

• Easily moved at any corner of foundry

• Available in single, double & three deck models

• Capacity : 3 TPH

• Motor : 1 H.P.

SMT sand muller is designed for mixing of heterogeneous mass of two or more dry or wet material into homogeneous uniformly blended and bonded product. This machine is sturdy designed made from heavy channels and plates. The rollers are spring loaded to adjust mulling pressure.

• Accessories : auto sand charging system, automatic cycle control, carbide tipped scraper blades, linings for drums, sand aerator.

• SMT sand mullers are provided with sand aerator, sand charging system, carbide blades and S. S. linings. Capacity 50 kgs to 1 ton. Ganesh has taken plunge to automize the existing sand muller into highly productive one.

We give customize solution to your existing mullers and improve productivity with minimum human dependence.

• Muller capacity - 75, 125, 175, 250, 350, & 500 kg

• Mixer capacity - 50, 100, 150, 200, 300, & 500 kg

• Rollers are spring loaded

• Auto charging system, cycle control can be made to accommodate additional facilities

Copyright © 2020. Southern Meta Tech. All Rights Reserved